The whole project might already be known to most of you, but for the records and especially for those 11 paper modelers worldwide who don't know it yet: To pay tribute to the lunar landing as a major act of mankind, the three most important hardware components will be created as exact replicas in the 1/96 cardboard model - the Crawler Transporter, the launch platform with the Launcher Umbilical Tower (LUT) as well as the Saturn V with the Apollo Spacecraft and the Lunar Module.

Apollo 11 Rollout - Courtesy of NASA

The planned completion date is 2009, in time for the 40th anniversary of the first moon landing. Whether the date will be kept is not so sure in view of the progress of the last 5 years ;)

The originally planned laser cut was rejected for the time being for cost reasons - so it remains a classical cardboard model of monumental dimensions - the height of the model is about 160cm.

The first part of the project, the Crawler Transporter, is now in its final phase. The main difficulty from the beginning was to find plans and historical pictorial material for it. Even though the crawler, the largest land vehicle in the world, represented a top technical achievement so far, it not only literally always stood in the shadow of the Saturn V and the LUT and was therefore rarely documented.

Crawler Transporter at KSC around 1966. Courtesy of NASA

One of the rare color photos of the Crawler Transporter from the time of the Apollo space program. The photo was taken around 1966 before its approval by NASA, recognizable by the logo of the manufacturer Marion Power Shovel Company at the front of the Cab.

The crown of the largest land vehicle in the world had to be ceded by the Crawler to the Excavator 288 not before 1978, and even that only partially, since the Excavator 288 is not self-propelled and therefore actually to be regarded as a construction machine - so the Crawler is still the largest self-propelled land vehicle in the world, and moreover the longest serving hardware in space travel at all. After the end of the Apollo program, the two crawlers were only slightly adapted for the Space Shuttle program, and are still in use today. A second, more extensive modernization did not take place until 2003.

The Crawler Transporter today, after the second modernization in 2003. Courtesy of NASA

The crawler is about 40m long and 34m wide, and weighs about 2,500t unloaded. The trucks have a total output of 6,000 hp, the maximum speed is 1.6 km/h when loaded.

Schematic representation of the Crawler Transporter. Courtesy of NASA

Why the gigantic effort of the transport from the VAB (Vertical Assembly Building, later Vehicle Assembly Building) to the Launch Complex 39 more than 6km away? When the Saturn V was launched, the energy of a Hiroshima bomb was released. A worst-case on-site would have destroyed the entire infrastructure. There were several transport options for the Saturn (lying / standing, water / land, rail / track), the decision for the standing concept was obvious, as horizontal storage of the Saturn would have been problematic due to its own weight, and the erection before launch would have caused enormous problems. The decision against a rail-based concept in favor of the crawler was made because of the crawler's better shock and vibration characteristics and the ability to overcome gradients.

Apollo 9 climbing the launch pad. Courtesy of NASA

The load of about 5.400t rests on the 4 points above the Guide Tubes, which form a square of 27,4m length. The weight is carried by the 16 hydraulic JEL (Jacking/Equalizing/Leveling) cylinders, which level the Saturn and the launch tower to an accuracy of 1/10 of a degree - also, as can be seen above, on the 5° ascent to the launch ramp.

The crawler in the construction phase. Courtesy of NASA

The crawlers were built directly on site, a transport would not have been possible. The construction time was 2 years, and was accompanied by numerous rebuilds and new constructions. The first crawler was officially put into service in February 1966.

The Model

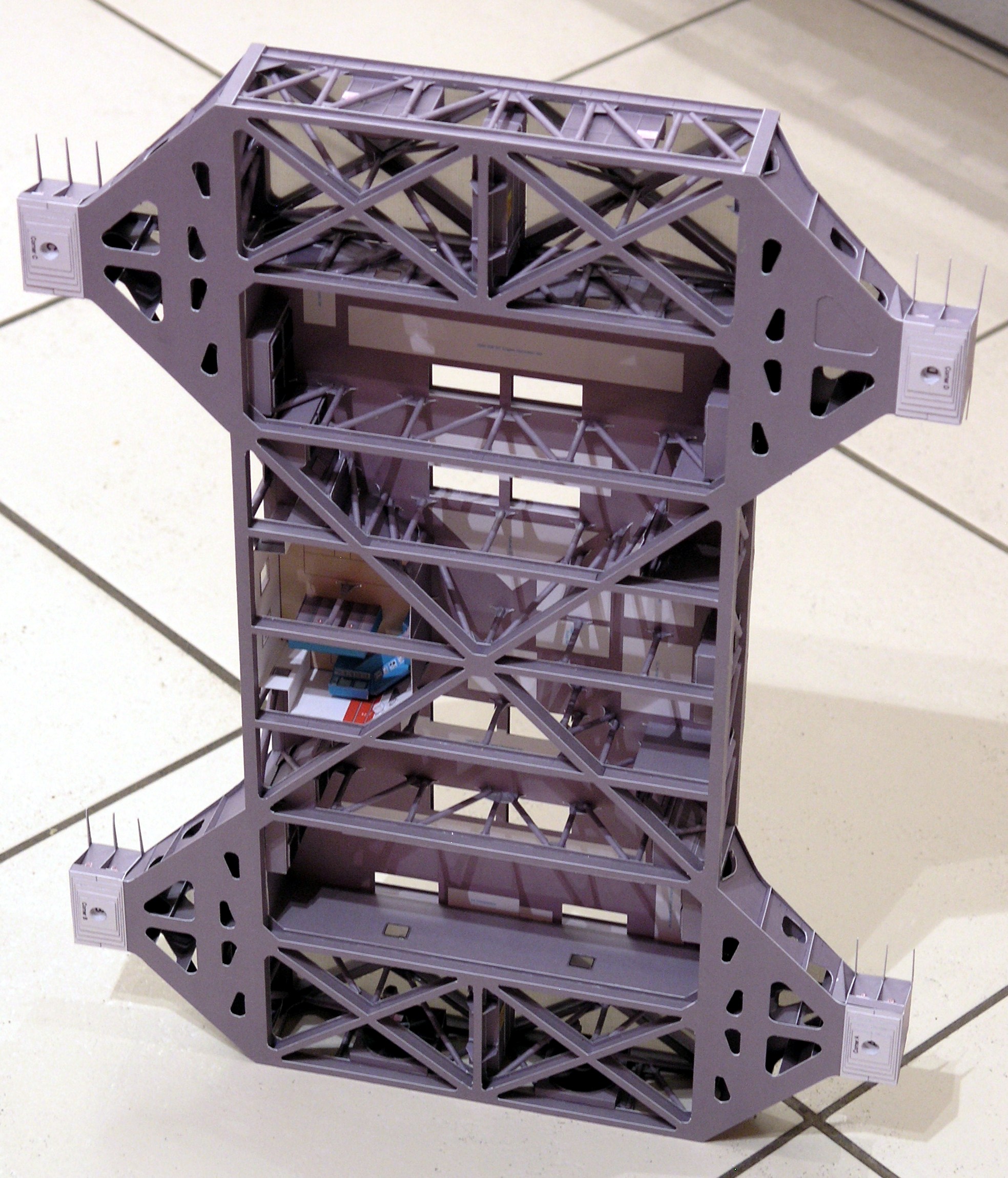

The chassis of the crawler model

The model follows very meticulously the original NASA construction, even the used sheet thicknesses could be converted to a large extent true to scale, which is to be owed to the lucky circumstance that it turns out quite well coincidentally. As mentioned at the beginning, the main difficulty was to find sufficient reference material. Fortunately, an unofficial source close to NASA opened up and sent me countless scans of original blueprints from the time the crawler was assembled.

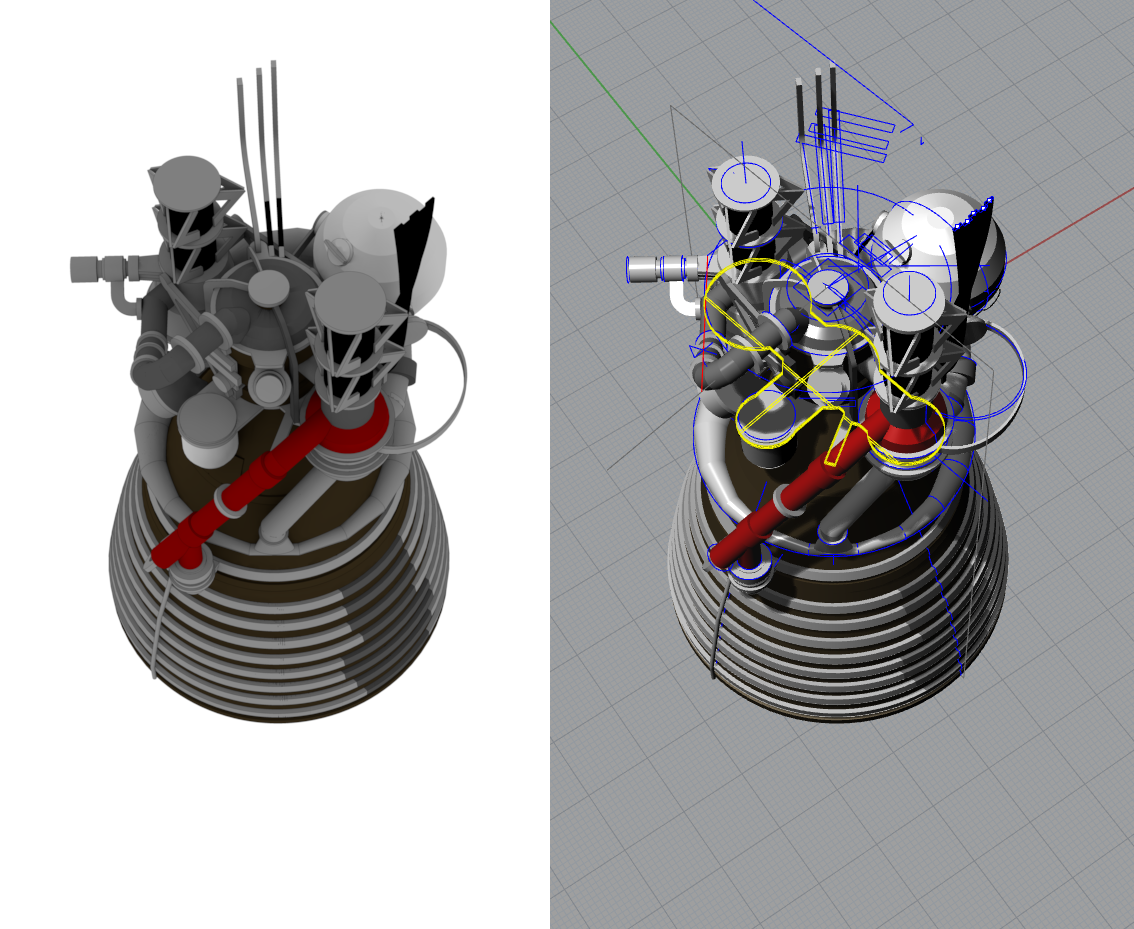

Original design document of the Main Sprocket. Courtesy of NASA

As an example, the design drawing of the 13-sided drive wheel of the Crawler Truck is shown here. The dimensions are all in inches, and often the material thickness has to be added to the final dimension, which is important for us model builders and constructors. Also, the dimensions can sometimes hardly be deciphered, so that they have to be derived plausibly from other dimensions.

... and in real.

The model is constructed entirely in Rhino 3D - first the NASA plans were implemented, then the real model parts were designed. This rather complex procedure ensures that the modeling is as detailed as possible. The level of detail and difficulty is enormously high, which is why the skill level was already designed scalable during the planning of the model - many details can be omitted or - for the completely insane - extended. The current number of parts is 9,300, but there will be more to come.

As the chassis serves as a platform for the Saturn and LUT, it is subject to very critical requirements with regard to height fluctuations and distortions, which is why it is designed in such a way that small inaccuracies in the individual parts are tolerated and cannot accumulate. This makes the assembly a bit more difficult, but the chassis remains the same. By the way, the construction is extremely stiff - I have already successfully had the Revell-Saturn V carried by the chassis.

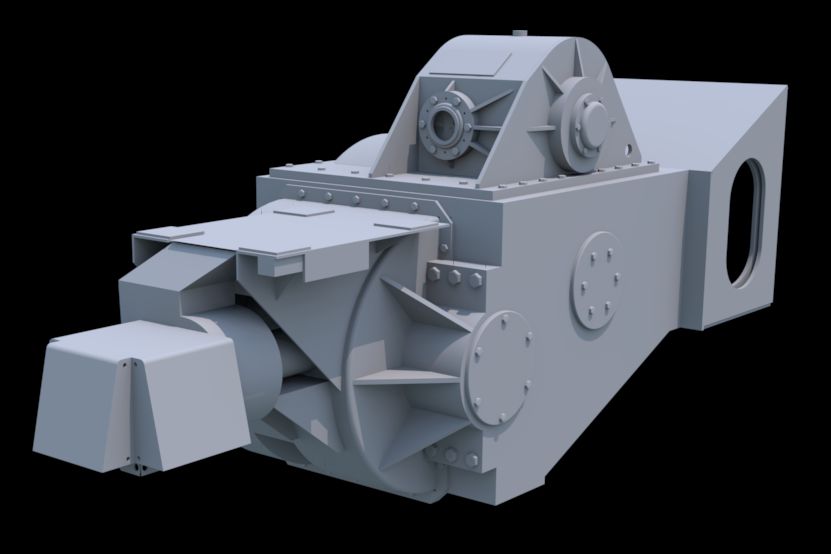

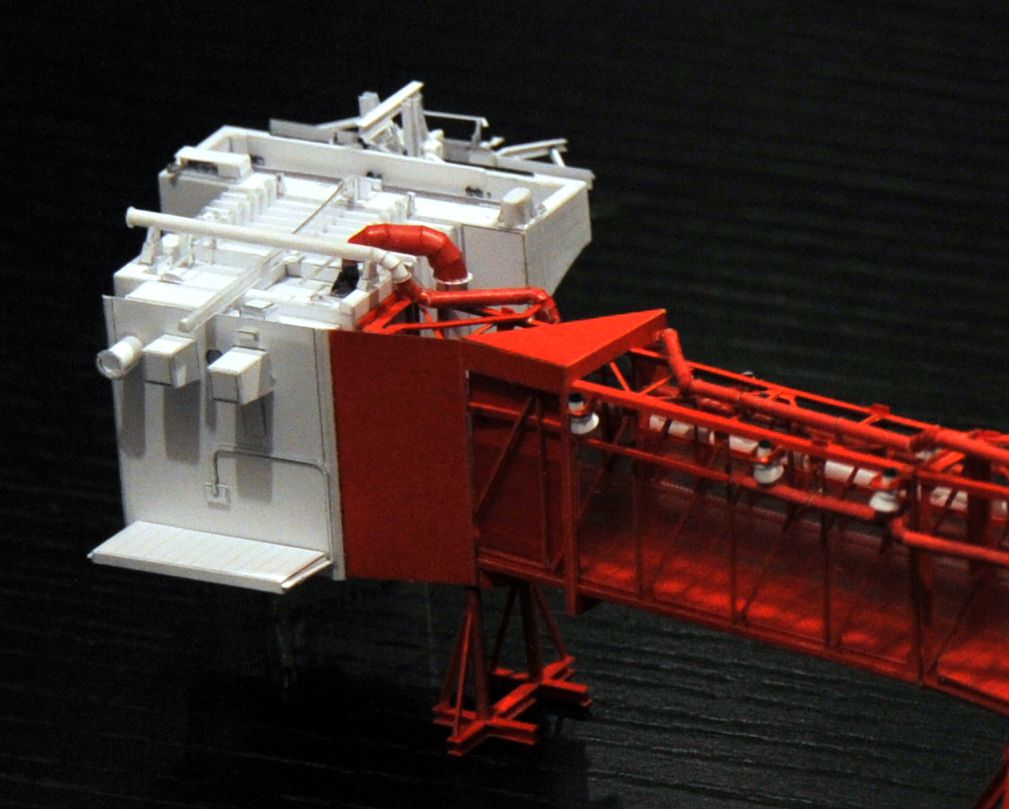

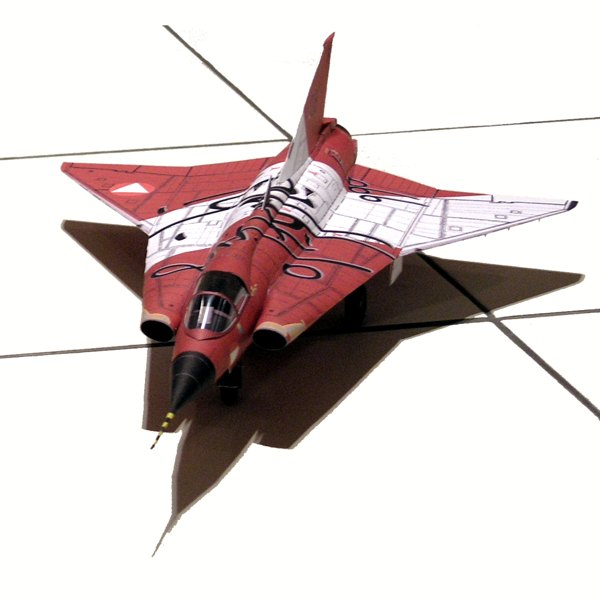

Test construction of the truck

The outer bearing house with the chain belt, the parts are just put together for demonstration and not glued yet, so the seat does not fit 100% yet

The gearbox house and the propel motor

At the moment the final version of the trucks is being tested - if everything fits here I will look for two volunteers who will build a truck as beta-testers. As a reward you will receive eternal fame in the preamble of the building instructions, as well as a kit of the crawler with the serial number below 10, hand-numbered and signed ;) - So if you feel addressed please contact me - here are the details (but I will put everything in a separate article):

- the construction must be done in the highest level of detail, so it's very difficult. You should have extraordinary modeling skills, and be best friend with micro parts.

- You will get the truck sheets printed. You are not allowed to make public statements about the beta-test. Feedback to me is of course very welcome.